Keynote Speakers

Prof. Ming-Chun Lu

Distinguished Professor, Department of Environmental Engineering, National Chung Hsing University, TaiwanSpeech Title: Application of Fluidized-Bed Homogeneous Crystallization Technology for Resource Recovery from Wastewater and Carbon Dioxide Capture from Flue Gas

Abstract: This presentation will introduce the revolutionary fluidized bed homogeneous crystallization technology, a world-leading advancement in recovering metal and non-metal ions from water without heterogeneous seeding. This innovative technology combines multiple treatment functions in a single fluidized bed reactor, occupying just one-third of the land area required by traditional precipitation processes. The resulting granular crystals have a remarkably low water content of only 5%, offering significant cost savings—up to 60% in sludge treatment costs, even when treated as waste. Additionally, because heterogeneous crystal seeds are not used, this technology can produce high-purity crystals that are reusable. From a carbon reduction perspective, this crystallization method boasts higher dehydration efficiency, reducing carbon dioxide emissions by nearly 300 kilograms per ton compared to sludge produced by traditional chemical precipitation methods.

This innovative crystallization technology can also be combined with carbon dioxide alkaline absorption to effectively convert carbon dioxide from factory flue gas into carbonate. The carbonate then undergoes a crystallization reaction in the fluidized bed reactor, producing calcium carbonate granules with calcium ions. The absorption liquid used in the crystallization tank is recycled back to the absorption tank, enhancing process sustainability. One of the key strengths of this technology lies in its high carbon dioxide capture efficiency, achieving a cross-sectional area loading of up to 20 kg CO2/m2/hr. This demonstrates its effectiveness in capturing carbon dioxide from flue gas streams. During the presentation, specific design and operating parameters will be discussed, along with an exploration of the granulation mechanism, which plays a crucial role in forming high-quality calcium carbonate crystals.

Prof. Kotohiro Nomura

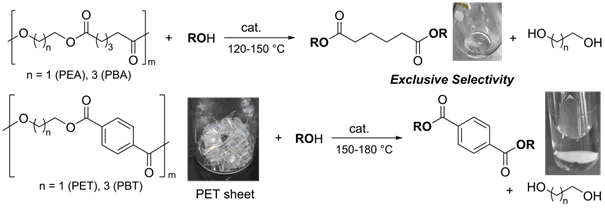

Department of Chemistry, Tokyo Metropolitan University, JapanSpeech Title: Chemical Recycling of Polyesters through Catalytic Depolymerization by Transesterification

Abstract: Chemical recycling, chemical conversion of used plastics to raw materials (monomers), has been recognized as an important technology for solving our concern in the plastic waste. Conversion of the plastic waste to value-added chemicals (called upcycling) has also been considered as an important technology in terms not only of circular economy, but also of development of chemical process from new alternative resources. Polyesters, exemplified as poly(ethylene terephthalate) (PET), are widely used as commodity thermoplastics, and PET has been reused as transparent bottles partly by so called mechanical recycling through a process of collection, sorting, cleaning, melting and reprocessing. However, due to inferior quality of PET reused resin compared to the fresh one derived from petroleum, there have been a strong demand to increase the percentage of called “closed loop recycling”, and an importance of the chemical recycling has thus been pronounced recently.

This presentation introduces the acid-, base-free depolymerization of various polyesters (PET, PBT, PEA, PBT, shown below) through the catalytic transesterification with alcohols. These depolymerizations proceed with exlusive selectivity without accompanying by-product and enabled to convert to starting monomers in exclusive selectivity, yields. Various alcohols can be used and the method thus enabled to proceed one-pot closed-loop chemical recycling through depolymerization‒repolymerization. As our more recent effort, acid-, base-free depolymerization of PET with ethanol by FeCl3 gave diethyl terephthalate (DET) and ethylene glycol (EG) exclusively (98->99 %). Successful exclusive, selective depolymerization of PET from the textile waste to afford DET (and recovered cotton waste) in the presence of FeCl3 catalyst could be demonstrated, strongly suggesting the possibility of chemical recycling of textile waste by adopting this catalysis.

Keywords: chemical recycling, polyester, PET, catalyst, transesterification, depolymerization, plastic waste, textile waste

Acknowledgements: This project was partly supported by JST-CREST (JPMJCR21L5).

References: For example, Nomura, K. et al. ACS Sustainable Chem. Eng. 2022, 10, 12504; 12684; Catalysts 2023, 13, 421 (special issue, invited); ACS Org. Inorg. Au 2023, 6, 377; Ind. Chem Mat. 2024, 3, web released; https://sciencesources.eurekalert.org/news-releases/1055991

Prof. Zhimin Qiang

School of Environmental Science and Engineering, Shanghai Jiao Tong University, ChinaSpeech Title: Microbial inactivation and reactivation during water disinfection with dual-wavelength UV radiation

Abstract: Emerging mercury-free UV sources, such as krypton chloride excimer (KrCl*) lamps and UV light emitting diodes (UV-LEDs), emit diverse wavelengths with distinct inactivation mechanisms. Hence, their combined application has the potential to improve disinfection effectiveness through synergism. In this study, a mini-fluidic photoreaction system equipped with a KrCl* lamp (222 nm) and a strip of UV-LEDs (275 nm) was developed, which could individually/simultaneously deliver accurate UV radiation at 222 nm (0.32 mW cm−2) or/and 275 nm (0.50 mW cm−2). Dual-wavelength UV (DWUV) radiation exhibited a substantial synergistic effect on Escherichia coli (E. coli) inactivation with a synergistic coefficient reaching up to 1.92, while no synergism was observed for PR772 bacteriophage (PR772) inactivation. Moreover, DWUV radiation significantly (p < 0.05) suppressed E. coli and PR772 reactivation in subsequent light/dark treatment. For E. coli, the underlying mechanism could be ascribed to the increased level of reactive oxygen species induced by DWUV radiation, which not only enhanced inactivation by damaging proteins and lipids, but also suppressed reactivation by damaging DNA repair enzymes. For PR772, although the DNA and protein damages caused by DWUV radiation did not yield a synergistic effect, the protein damage prevented the viral DNA from entering the host cells for repair, thereby suppressing the reactivation. This study helps develop more effective UV disinfection technologies by using DWUV radiation.

Keywords: dual-wavelength UV radiation; microbial inactivation; microbial reactivation; mechanisms; water disinfection

Prof. Yao-Tung Lin

Lifetime Distinguished Professor, Department of Soil and Environmental Sciences, National Chung Hsiung University, TaiwanSpeech Title: Identifying Biophysical Properties and Organelle Interaction Mapping in Foodborne Microorganisms Treated with Eco-Friendly Packaging Films Derived from Agricultural Waste

Abstract: With growing attention to fresh-keeping packaging, this study addresses food safety challenges in the perishable meat industry. Herein, we explore the disinfection mechanism of foodborne microorganisms through an innovative CTS-JAE film derived from shrimp shell chitosan and jaboticaba extract. Advanced imaging techniques—transmission X-ray microscopy (TXM), soft X-ray tomography (SXT), atomic force microscopy (AFM), transmission electron microscopy (TEM), and scanning electron microscopy (SEM)—were applied to map and quantify organelle interactions and subcellular structures. These methods revealed changes in biophysical properties (cellular roughness, adhesion, height, modulus, 3D cellular structure, and organelle interactions) of Escherichia coli, Staphylococcus aureus, and Aspergillus niger exposed to the CTS-JAE film. CTS-JAE film was also tested for preserving pork loin at 4 °C over 21 days, assessing pH, total volatile basic nitrogen (TVBN), lipid oxidation, total bacterial count (TBC), and color changes compared to polyethylene (PE) and pure CTS films. Results show that the CTS-JAE 20% film achieved a 99.999% bacterial disinfection rate within 24 hours, surpassing conventional PE film. SEM and TXM demonstrated significant microbial structural damage, including cell membrane integrity and shape loss, leading to K+ leakage and decreased survival. SXT and AFM provided nanoscale mapping of subcellular structures, uncovering detailed organelle interactions and structural alterations and giving new insights into microbial inactivation mechanisms. Overall, TXM, SXT, AFM, and SEM techniques reveal the extent of cellular and subcellular damage induced by CTS-JAE films. Additionally, CTS-JAE films extended pork shelf life from 6 to 18 days under cold storage, with maintained quality parameters: pH (5.75), TVBN (14.4 mg/100g), lipid oxidation (0.817 mg/kg), and bacterial growth (5.43 log CFU/g), outperforming PE film and unpackaged samples. Compared to pure CTS, CTS-JAE showed improved antioxidant capacity and sustained JAE release into food simulants. This innovative CTS-JAE film represents a promising, sustainable alternative to conventional plastics, enhancing food storage quality and safety.